TN10

These locknuts provide positive locking in applications with limited space. TAN / TAN locknuts are 25-50% thinner than our standard N or AN locknuts, but share the same thread pitch.

Features and benefits

- Thin section fastener that shares thread pitch with standard series.

- Comprehensive size range.

- Simple installation and removal.

- Standard Locknut sets the industry locknut standard

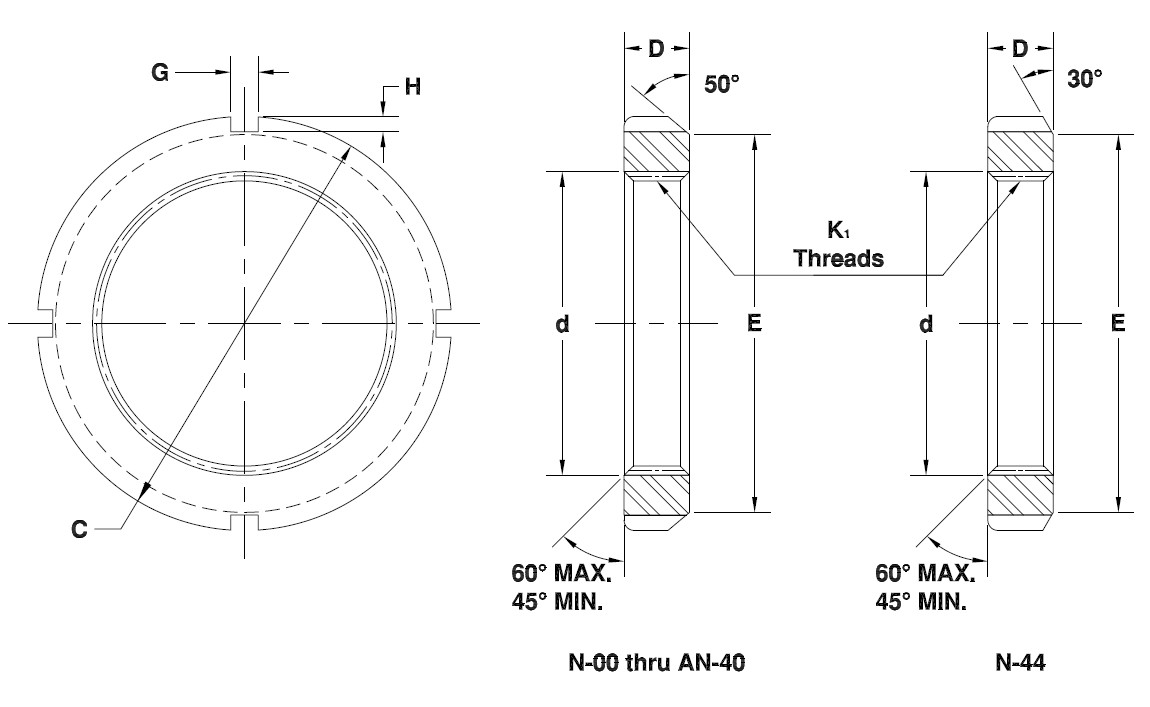

- Locknuts have four, equally spaced slots around their circumference to accommodate a hook or impact spanner.

- TN00 and TAN00 locknuts are commonly used with 231 and 232 series spherical roller bearings.

- Can be mounted directly to the shaft or via an adapter sleeve.

- TN / TAN locknuts can be reused, provided they are not damaged. A new lockwasher should be used each time the corresponding locknut is installed.

- Lockwashers are available for thread 0.391 to 8.628 in. (sizes 00 to 44)

- Provide operational and installation clearances, higher installed accuracy, and lower rotating imbalance loads than hexagonal or square locknuts.

- Conform with ABMA, SAE and ABEC standards for bearing and power transmission applications.Bearing face / pitch diameter runout will not exceed .002 inches for sizes 00 through 06,.004 inches for sizes 07 through 22, and .006 inches for sizes above 22.

- Manufactured from AISI grade 1000 or 1200 series steel.

- Bearing face surface finish will not exceed 100 microinches for sizes 00-10, 120 microinches for sizes 11-22, and 150 microinches for sizes above 22.

- Use with series TW and WTH lockwashers.

- Manufactured with ANSI Class 3 threads.

- Most suitable for machine tool, gearbox and aerospace applications with rolling element bearings, cams, clutches, gears, pulleys, sprockets, and sleeve assemblies.

| Dimensions |

|---|